1. Explanatory notes for scope 1,2 & 3

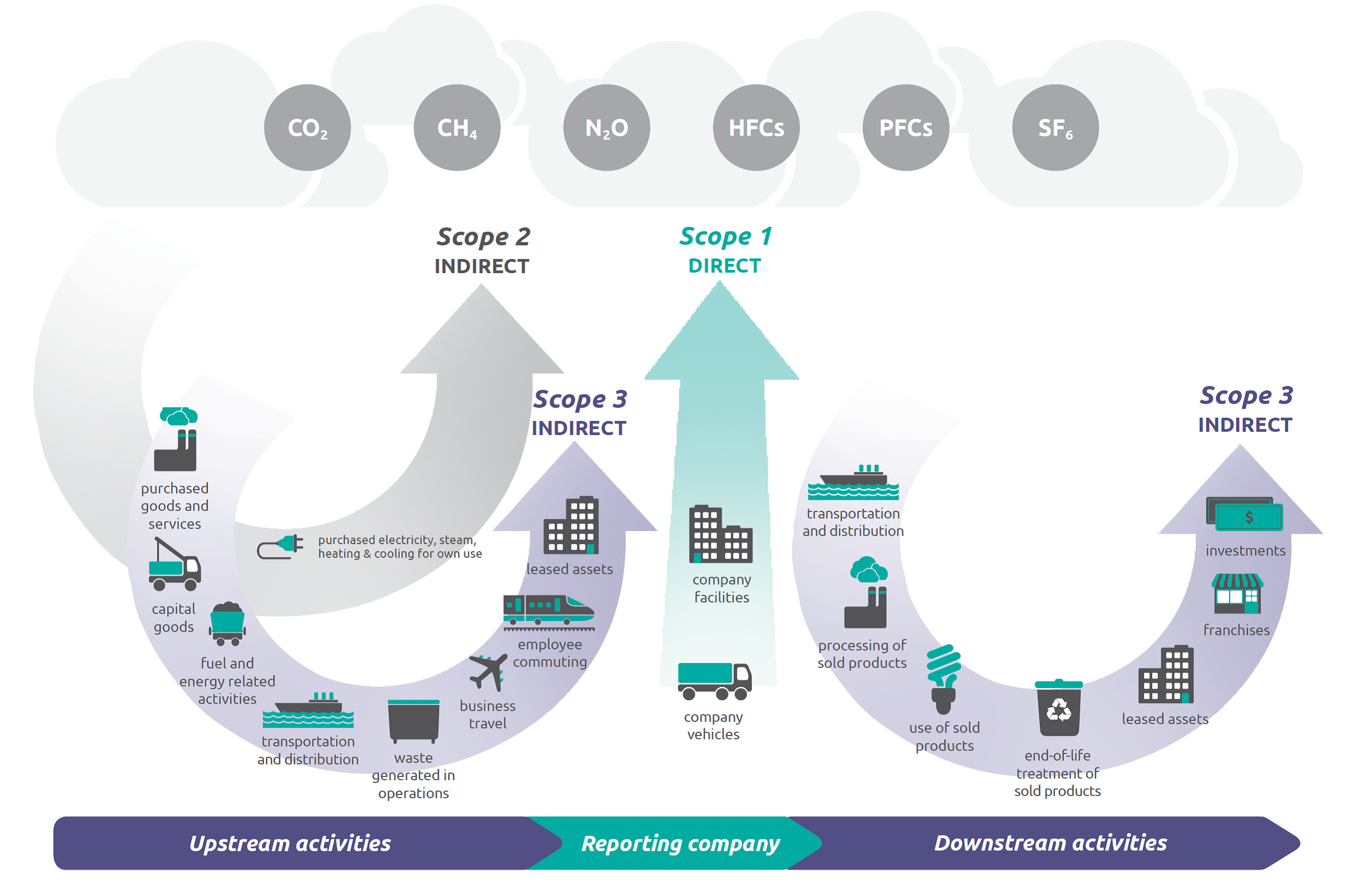

Scope 1: Direct emissions from operational activities

Scope 2: Indirect emissions from the consumption of purchased electricity from the grid

Scope 3: Indirect emissions from the up- & downstream of an organisation's value chain

In the report scope 1 and 2 were calculated as a whole, at least 66% of scope 3 was included.

The activities that cause emissions within Mistral Home are:

- Electricity consumption for:

- Office activities;

- Lighting;

- Other technical and production related installations.

- Natural gas consumption for: heating of buildings;

- Production and transport of purchased materials and services (scope 3):

- Textiles;

- Packaging materials;

- Office materials;

- Etc.

- Waste disposal and processing;

- Upstream and downstream transport of goods;

- Home to work commuting;

- Energy-related emissions.

Scope 1 and 2

In total Mistral Home was responsible for 250,51 ton of CO2 emissions in 2020, of which 94,77% can be attributed to scope 1.

The biggest contributors to scope 1 were the petrol used in the company cars (75,2 ton) and the natural gas used for MH2 (162,2 ton).

The remaining 5,23% is attributed to scope 2, worth 13,10 tons of CO2.

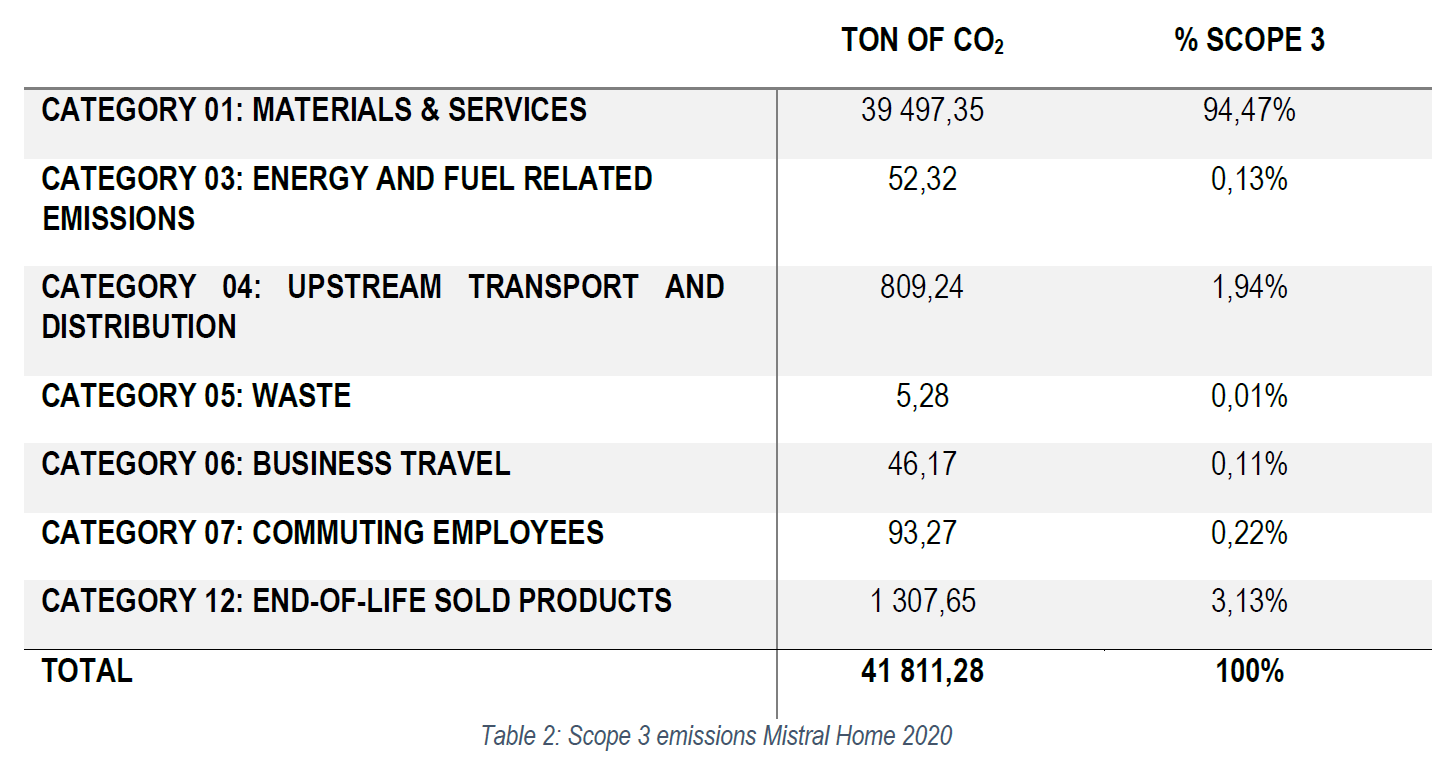

Scope 3

Although scope 3 does not have to be included in the reduction plan, we chose to do so. Considering the business in which Mistral Home is active, the textile business, we are producing a considerable tonnage of CO2 emissions within scope 3.

Out of 15 categories within scope 3, 6 turned out to be relevant for us. These categories have internationally standardised names & numbers.

2. Identification of reduction measurements applying to Mistral Home

Scope 1

- Stationary combustion :alternative space heating MH2

- Mobile combustion: decrease combustion of fossil fuels from a mobile installation or cars

- Fugitive emissions: greenhouse gas emissions from installations operating on greenhouse gases

e.g. the emissions of cooling agent from a cooling installation due to a leak, for Mistral Home this is HVAC in MH1

Scope 2

- Identify zero-load consumption

- Raise awareness

- Relighting LED - MH 1

- PV installation - MH1

- Green power - MH 2

Scope 3

Category 01: Materials & services

1. End products

At the source of our high CO2 emissions within scope 3 lay two textiles: polyester and cotton. These account respectively for 53.30% and 40.40% of the scope 3 emissions. Together they are responsible for 93.70%.

It has been known for some time now that the textile industry is a heavy polluter, and this is now painfully clear once again in these figures. For years, we have been researching and developing alternatives to reduce the polluting factor of our products. Take our cotton-viscose duvet covers, for example.

The carbon footprint of textiles is not calculated in the same way as an organisation's footprint, but by looking at the entire life cycle. All input and output flows are converted into a CO2 equivalent impact.

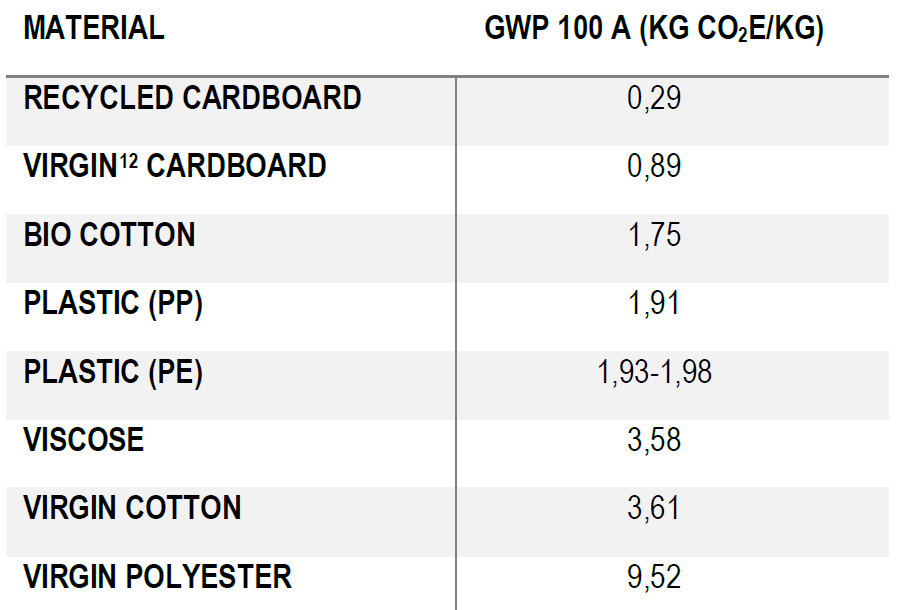

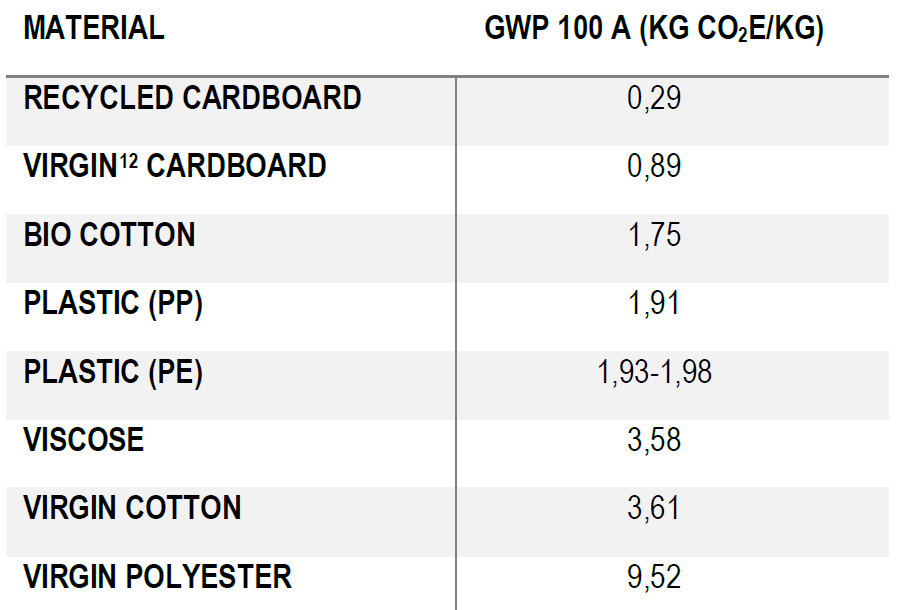

In general, the carbon footprint of textiles is expressed in CO2e/kg. A comparative table of different materials per kilogram is given below.

Polyester is much more polluting than cotton as cotton is a crop that absorbs CO2 from the atmosphere. Cotton also requires far fewer chemicals for processing than polyester. For the latter, crude oil is used as a raw material, which in turn requires large amounts of energy during the production process. This makes the production of polyester factor 2 to 3 times more energy intensive than that of cotton.

We continue to research new materials in order to come to a more sustainable product, for example, hemp is now also being considered within the textile industry. It grows much faster than cotton, it can grow up to 3 meter over a period of 100 days, per hectare, it can absorb as much as 22 tonnes of CO2. It is also said to last 5 times longer than cotton products and is biodegradable.

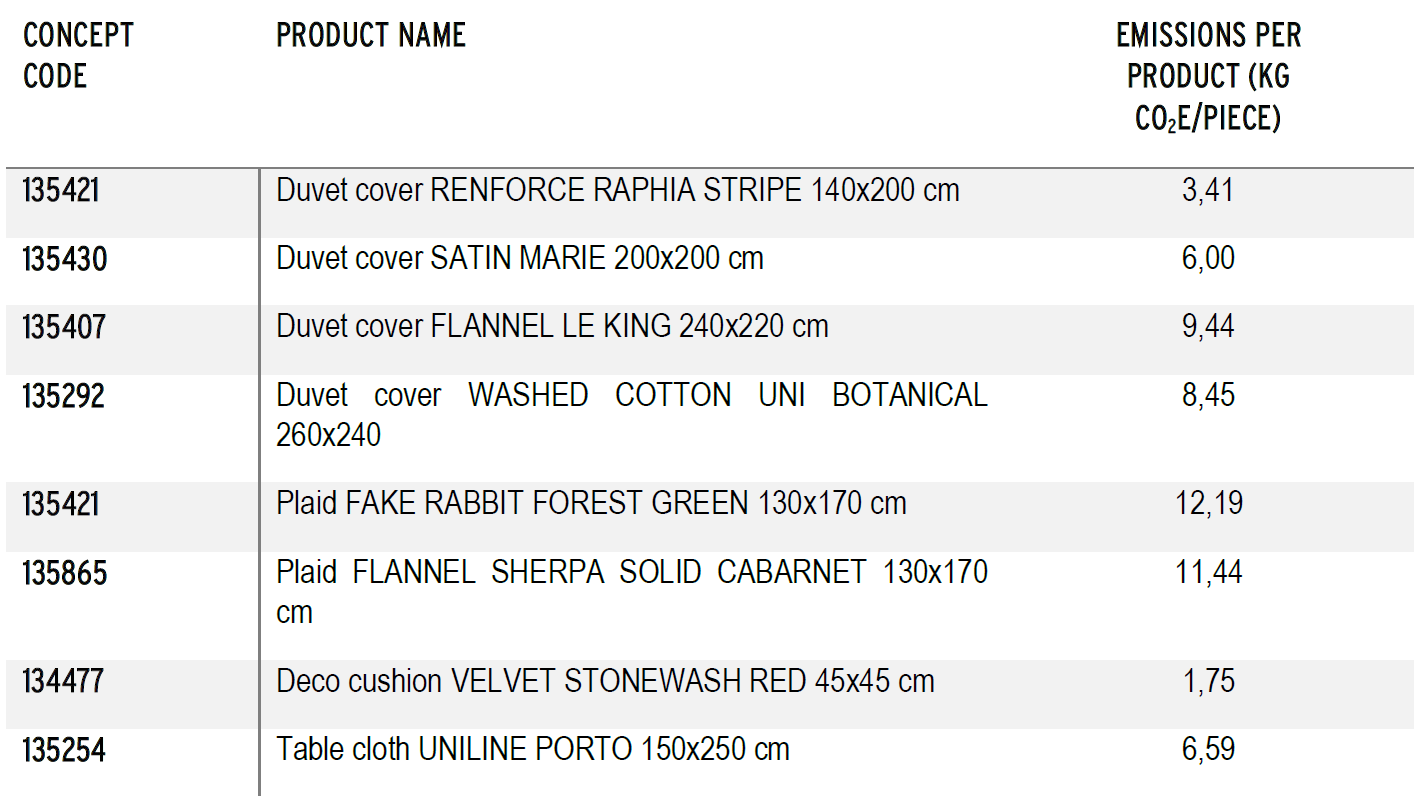

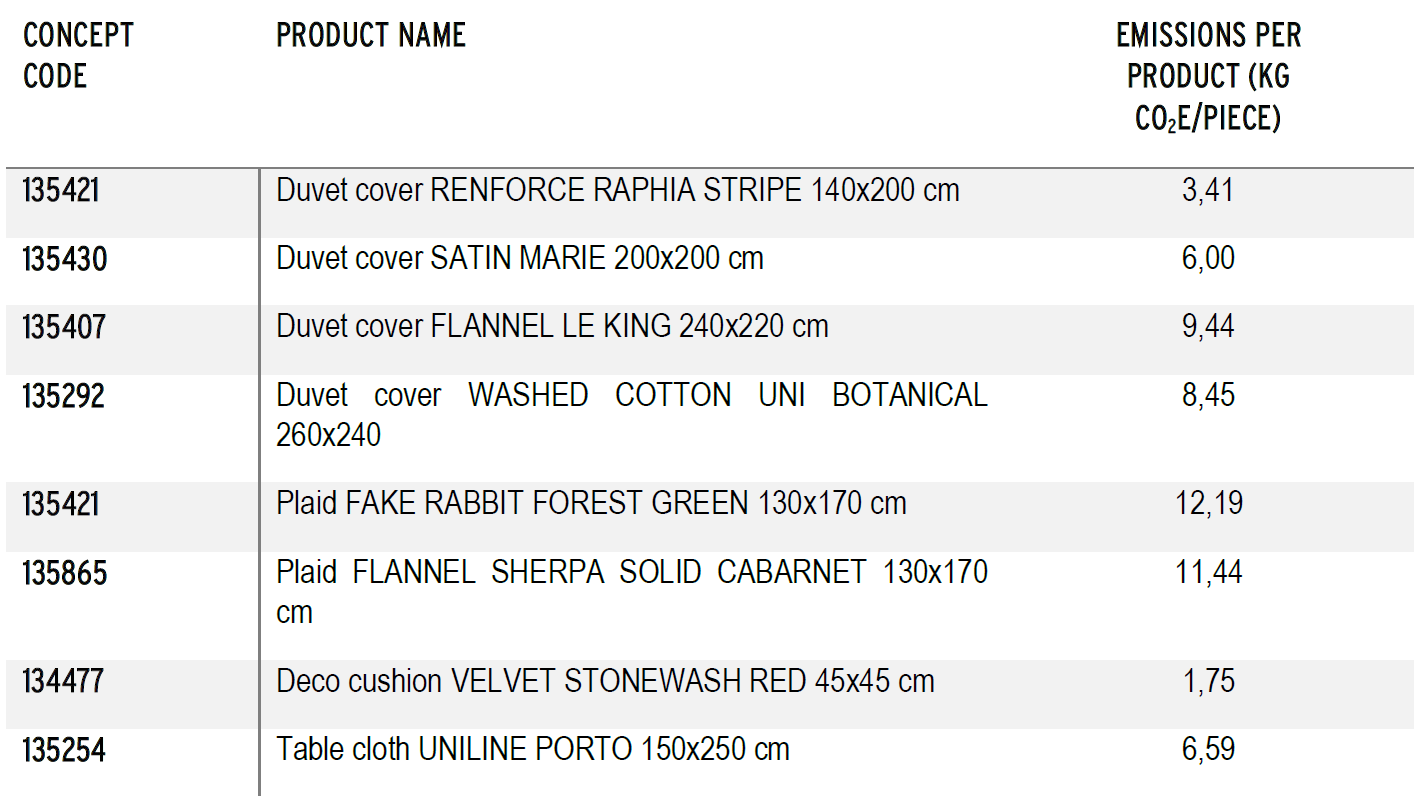

Here are some of our products from the autumn-winter 2021 collection and their respective CO2 emissions as an illustration. These emissions were calculated based on their net weight (without packaging) and the composition of the fabrics.

Ultimately, we can make our end product less polluting by also looking at:

- Transport of goods from the factory to the production site

- The energy consumed to manufacture these products

- Transport of these products to the retail and end consumer

- The use phase of products (in the washing machine, hand washing, etc.)

- The end-of-life treatment (incineration, recycling, etc.)

2. Sustainable procurement policy

Through a sustainable purchasing policy, we use our purchasing power and influence in our relationships with suppliers and customers to improve the social and environmental performance of the entire product chain. An effective way to ensure sustainability within a chain is to integrate requirements into the selection process of potential suppliers.

These criteria may relate to the company (ethical management, safety, environment, etc.) or to the products supplied (FSC, GRS, etc.)

3. Packaging materials

In recent years, no exact records have been kept of which packaging was used for each product, so we cannot give accurate statistics on this.

There are different types of plastic and cardboard, some of which are more or less polluting than others. Here is a brief summary:

- Virgin material

New material produced from raw materials of fossil nature. - Recycled

Material that for a certain percentage consists of recycled raw materials of fossil nature or inorganic waste flows. - Bio-based material

Material that for a certain percentage consists of raw materials of biological origin. This includes all raw materials of plant or animal origin, both new products and waste streams (vegetable oils, residues from maize production, etc.)

For several years now, all our plastic packaging has been biodegradable, although this is not indicated on the packaging. Since the middle of 2021, we have also been working on packaging that is as plastic-free as possible. Sadly, we are often bound by the customer's wishes in this respect, but we offer the plastic-free variant wherever possible. This only consists of the product itself and cardboard.

Category 03: Energy and fuel related emissions

In this category we find emissions related to the production of fuels and energy purchased and consumed by Mistral Home that are not included in scope 1 & 2.

The biggest progress we have already made in this regard is installing solar panels (generating our own green electricity) and switching from purchasing grey to green electricity from our energy supplier.

By green power we mean renewable energy (generated by wind, sun, etc.)

Category 04: Upstream transport and distribution

Here we group emissions caused by the burning of fossil fuels for transport and distribution of purchased materials and services via road, water, rail and airways. In general, the larger the vehicle within the same category, the more efficient the transport, the lower the emissions per unit distance.

The following table illustrates the carrying capacity and emissions per tkm (tonne-kilometre), this variable shows how much emission there is per kilometre when the weight of the payload is 1 tonne.

An additional reduction measure we could take if our customers are open to it is to replace the wooden EURO pallets with cardboard pallets. These have a lower embedded carbon footprint and are lighter in weight.

Category 05: Waste

In terms of waste, quite a few steps have already been taken. For instance, we reuse our cardboard boxes, fabric waste is donated to schools and textile waste is taken to Delorge, a company that recycles textile waste.

In the offices we focus on working as paperless as possible. We review individual single streams and reduce paper, still considering efficiency. We also review or shorten streams per department.

In addition, we also focus on informing and raising awareness amongst our colleagues.

To further reduce the waste mountain, we could establish additional partnerships with textile processing companies.

Category 06: Business travel

Given the 2020 corona pandemic, we cannot speak of representative figures here. The impact of business travel has consequently increased in 2021 compared to the previous year.

Category 07: Commuting employees

In terms of commuting, we choose to particularly incentivise the employees.

In the spring of 2021, a challenge was held at Mistral Home in which people could score points by coming to work by bike or by car pool. The department and the individual who had accumulated the most kilometres in doing so received prizes at our first Sustainability Day on 13 October 2021.

Since 2021, there has also been the option of leasing e-bikes. For a small fee, colleagues can use an e-bike and charge it at work.

Since November 2022, every Thursday has been a Green Thursday, when people come to work by bike or eat vegetarian on those days, they earn a point. These points can be exchanged for shopping credit on our webshop, valid only on sustainable products of course.

Category 12: End-of-life sold products

The end-of-life of textile products generally constitutes a difficult topic. Although the producing companies can indicate to the end consumer that these products should be recycled, it is ultimately the consumer who chooses what to do with them. More and more people take these products to a thrift shop, sell them on or take them to the container park, but unfortunately a significant proportion still ends up in the pile of residual waste.

A test project we could start in this regard would be to create a collection point for items purchased from our webshop, for example. We could then ensure that these products are recycled in a sustainable way.

However, this is still an idea at the moment and needs to be worked out thoroughly in order to be successful. To be continued.

3. Summary company carbon footprint 2020

As a company, we have chosen to commit to the 1,5°C target of the Science Bases Targets Initiative at the SME level. This target will be evaluated annually and adjusted if necessary.

This target implies that by 2030 we aim for an absolute reduction of CO2 emissions in scope 1 & 2 in order to limit global warming to 1,5°C compared to 2020.

To achieve this, Encon has worked out a reduction plan for us. The biggest steps that will be taken are:

- A fully electric car fleet;

- Only green electricity and no more extra polluting practices;

- Avoiding refrigerant leaks from cooling systems through regular inspection and maintenance;

- Making the heating of MH2 at least 11% greener, either by reducing the temperature or by replacing the systems.

In addition, we take great efforts year after year to reduce our scope 3 emissions, and it will continue to be a permanent focus of our attention.

We aspire to be a pioneer in sustainability in the textile industry. We are not there yet, but we are well on the way thanks to the commitment and motivation of our colleagues.